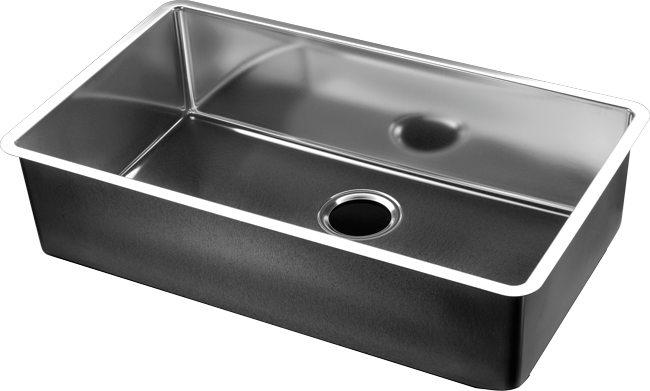

Mori 2A offers a wide choice of stainless steel sinks that can meet the standard demands of the market and that have successfully evolved over time to keep pace with new design trends.

This line includes products that satisfy the requirements of different sectors: from square and rectangular sinks for the industrial sector and the domestic sector, to cylindrical and hemispherical basins for the bathroom and for boats and caravans.

The production cycle used for the majority of our sinks is of fundamental importance: between the first and second deformation, we perform a heat treatment called “solubilization” which removes structural defects and dissolves the carbides. Before polishing, the sinks undergo a pickling treatment that restores the passive layer essential to resist corrosion.

Pickling and passivation are of primary importance, as this promotes precisely the mechanism behind the stainless quality of the steel, known as “self-passivation”.

In addition to the standard tumbled finish, other types of finish are available on request.

An antibacterial coating can also be applied to all of our sinks: ABACO® is able not only to prevent completely the proliferation of bacteria but also to eliminate it, guaranteeing perfect and lasting hygiene. Therefore, ABACO® has both a bacteriostatic and bactericidal effect.