NEWS

16 February 2021

DEEP DRAWING – Complete cycle for producing a sink

The purpose is to provide a practical application example to highlight the cold flexible deformation properties of austenitic stainless steels. We took advantage of the experience of a leading company of the sector to illustrate the main production steps.

Stainless steels in general and austenitic stainless steels in particular lend themselves very well to deep drawing; there are different types of drawing depending on the technology used and the geometry of the item; for the sink here considered, although the height is not excessive (200 mm), we are faced with deep drawing parameters due to the very small radii (radius 15 mm).

There are many aspects to be taken into account when deep drawing:There are many aspects to be taken into account when deep drawing:

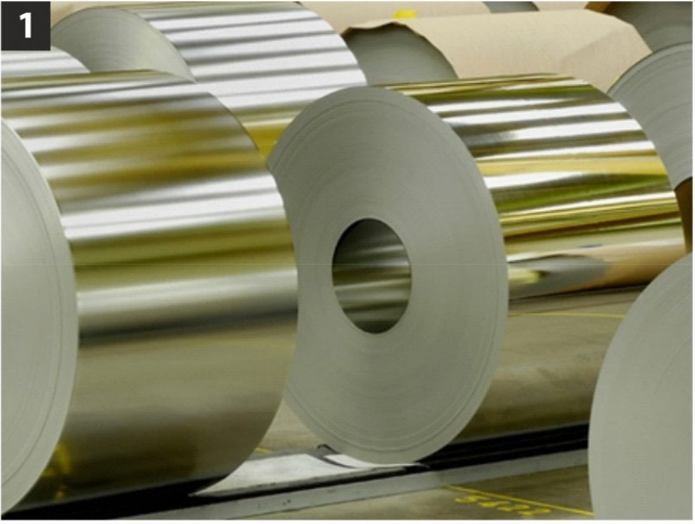

Raw material

AISI 304 (EN 1.4301) belongs to the austenitic steel family and is the most widely used. The company uses this type of stainless steel because it offers excellent performance in terms of deformation as well as guaranteeing excellent resistance to corrosion.

Preparation of the blank

The preparation of the blank, i.e. the preparation of the stainless steel sheet, which will then be deformed, is one of the most delicate and decisive production phases for the success of the product. In fact, the following are evaluated:

– The chemical composition of the raw material (18% Cr, 9% Ni, etc.).

– Mechanical characteristics of the raw material (elongation, hardness, yield strength, etc.).

– Grain size (ASTM scale)

– Work hardening index

– Anisotropy index

– Dimensions and geometrical shapes of the starting sheet

– Visual evaluation of the material quality aspect

Lubricant

One of the parameters that must be taken into account when deep-drawing stainless steels is the choice of the most appropriate lubricant. It should be borne in mind that this choice is at least as important as the choice of the other technological parameters. This is to clear the field of misconceptions such as that any lubricant will give excellent results or that with a good lubricant, mistakes made in the choice of other parameters can be rectified.

Deep-drawing

Deep drawing is a technological process by which the stainless steel sheet is plastically deformed and takes on a particular shape. This operation is carried out by means of hydraulic presses with different powers, on which a die is positioned and suitably fixed. The die can be made of different materials and consists, in a simplified way, of three components: punch, blank holder and die. Different presses are used: traditional deep-drawing with ‘candles’, deep-drawing from the bottom and triple effect deep-drawing.

Heat treatment

For some types of austenitic stainless steel, austenite is not totally stable at room temperature and may partially transform into martensite during cold plastic deformation. In this case, the steel may lose corrosion resistance and some physical characteristics (e.g. magnetic permeability), especially if it is heavily deformed. The original austenitic structure can however be restored by a heat treatment which involves rapid cooling at a high temperature (over 1000 °C), after solubilising any carbide present in the die. For this reason, this treatment is known as annealing and gives the stainless steel minimum hardness and excellent ductility, as well as the best resistance to corrosion.

Trimming and grinding

Trimming, also referred to as blanking, is a process whereby, using mechanical presses and very precise moulds, excess material is sheared off.

The trimming tool is made up of two components: die and punch. The clearance between the die and the punch and the hardness of the latter are defined according to the thickness of the article produced and its condition (annealed, hardened). Grinding is the machining operation following trimming, the purpose of which is to remove sharp parts. Austenitic stainless steels, due to their low thermal conductivity and high expansion coefficient, tend to overheat locally, so, in order to avoid spots of different colour and undesirable deformation especially on thin thicknesses, abrasives should not be used on the same point, but should be cooled appropriately.

Pickling and passivation

It is important that the surface is free from any elements (welding oxides, oils and greases, oxides due to thermal treatments, rusty contact elements, etc.) that may hinder or delay the formation of the passive film, which occurs spontaneously in a sufficiently oxidising and neutral environment. It is therefore necessary to guarantee a suitably pickled and passivated surface. The pickling process is divided into several stages:

– Degreasing at 70 °C

– Warm rinse with mains water

– Immersion in pickling solution

– Acid rinse (passivation)

– Mains water rinse

Surface finishing

There are various surface finishes that can be applied to a stainless steel product: electrolytic, mechanical mirror finish, scotch-brite, tumbled, tampico, shot peening with ceramic balls, etc.

The surface finishes, as well as having an obvious different aesthetic appearance, guarantee a different behaviour in terms of corrosion resistance, depending on the level of roughness that can be achieved.

Washing

Containers are placed in washing tunnels on conveyor belts and flooded with jets of controlled alkaline solution as they advance. The final stages of processing consist of a rinse with mains water and a final rinse with demineralised water. The parts are then dried at 11O °C and directed towards packaging.

DOMESTIC SINK WITH 15 mm RADIUS

The 15 mm radius bowls were strongly desired by architects and designers to enhance the aesthetics of domestic kitchens; they have been on the market for many years and, together with the “zero” radius bowls (obtainable by bending), have partially replaced the traditional bowls with large radii (60, 80, 90, 120, etc.).

PRODUCTION CYCLE SINK 15 AND DIMENSIONS 500×400 H. 200 mm

To produce a radius 15 sink with dimensions of 500×400 mm and a height of 200 mm, it is used an AISI 304 with a high nickel content (9%). The starting development is a sheet with dimensions 810×880 mm, thickness 1 mm and surface finish 2B. The sheet is suitably lubricated with high viscosity oil free of chlorine and sulphur and then positioned on the lower blank holder of the mould; the metal sheet is plastically deformed using a 700-tonne hydraulic press (deep-drawing from the bottom). In this first phase of the process, called first drawing, the aim is to get as close as possible to the shape and height of the finished product; the height obtained after this first operation is approximately 185 mm and the geometry of the part is very similar to that of the finished item.

Then, it is washed in a six-station washing tunnel (intense alkaline degreasing/soft alkaline degreasing/ hot rinsing/ mains water rinsing/ demineralised water rinsing/drying) before being placed in the electric oven for annealing at a temperature of 1050 °C for 13 to 15 minutes.

After appropriate cooling, the sink is taken to another hydraulic press to carry out the operation called calibration. For the second drawing, a 600 ton press with “candles” is used: the sink, suitably moistened with emulsifiable water, is deformed until it reaches its final geometry.

The process continues with cutting (mechanical gap frame press with a capacity of 200 tonnes) and the creation of the drain hole and overflow. Before the sink is transferred to the electroplating department, the trimmed edge is ground using an anthropomorphic robot.

Before immersion in the pickling tank, the parts are washed to prevent contamination of the galvanic bath. The passivated and properly washed sink can then enter the polishing departments. Finally, the final washing is carried out via a six-station tunnel.

Before packaging, achievable according to customer requirements, quality control is carried out on each individual tank. All process steps are traceable and internal procedures comply with the requirements of the general and specific MOCA regulations.

Written by Alvise Mori