NEUHEITEN

SOME CONSIDERATIONS ABOUT OUR VACUUM CONTAINERS

The preservation „sous vide“.

Preserving food is increasingly a necessity but unfortunately this is hindered by the contact of food with air (rich in oxygen that oxidizes food) and with the organisms that breathe it (many bacteria that live in food at room temperature).

In fact, through the air, oxygen and all the chemical and bacteriological contaminants contained, come into direct contact with food and quickly deteriorate it. This is why the food we try to store in the refrigerator, after a short time, become inedible and, indeed, dangerous to health.

There is a very effective remedy for all this: vacuum.

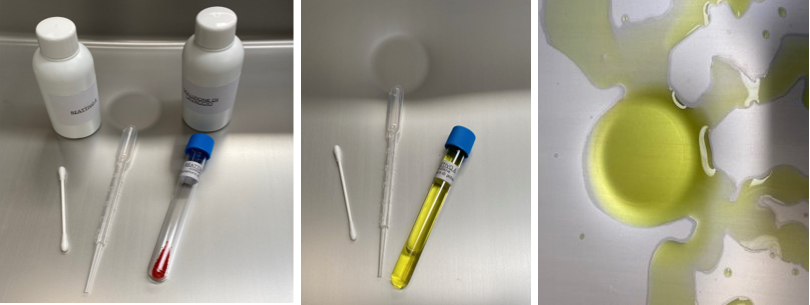

Vacuum is a method of food preservation that consists of sucking air from inside the container in which the food is stored and consequently placing the food under negative pressure. It is applicable to products both raw and cooked, of vegetable (vegetables and fruit) and animal origin (meat, fish, sausages). Sometimes vacuum can be associated with other conservation techniques, such as refrigeration, atmospheric modification using inert gases and both dry and wet brine.

.

Preserving food in an atmosphere poor in oxygen (which acts as an oxidizing agent), improves some specific characteristics:

– deterioration, slowing down the phenomena of proliferation of the bacterial load;

– the maintenance of the organoleptic characteristics, slowing down the fermentation phenomena;

– the maintenance of the original color, slowing down oxidation phenomena.

.

Among the advantages of vacuum maintenance, there is also the economic saving, deriving from being able to maintain for longer:

– freshly cooked food;

– food not completely consumed;

– food prepared in significant quantities and intended for periodic consumption.

Among the users who use containers for vacuum maintenance, we find industrial kitchens that prepare lunches for hospitals, clinics, nursing homes, school canteens, business canteens and the like. In these cases, in fact, the food is completely cooked in places other than those where it will be consumed and often located several kilometers away. If properly stored in vacuum containers, food can be conveniently transported without risk of deterioration and contamination, and then served and/or simply heated once it reaches its destination.

.

Our range.

Our vacuum containers have been developed and manufactured in order to guarantee:

– resistance to deformation, resulting from both use and negative pressures generated by air extraction, which could affect the vacuum seal;

– reliability in terms of release of migrating substances, being able to comply with the most recent European regulations regarding migration testing (MOCA Reg.);

– traceability, as our company has implemented a control system based on Good Manufacturing Practices (GMP);

– easy cleaning and sanitation thanks to the perfect surface finish.

Lids model 1/1 and 1/2 are available in stainless steel with transparent valve (BPA FREE) while lids model 1/3 are available in Tritan (co-polyester BPA FREE).

.

.

Some tips for use.

It is important to specify that our vacuum containers and lids are designed for storage and not for cooking at high temperatures.

.

If the lids are subjected to high temperatures (over 200°C) they may be damaged by the gasket, which guarantees the perfect hermetic coupling between lid and gasket; although this is made of food grade silicone with resistance up to 220°C, the primer which ensures its adhesion to the lid may be irreversibly damaged.

.

In case of storage in the refrigerator, we recommend not to go below -18°C.

.

The first advice, therefore, is to make sure that the containers are used only for heating the food, and are therefore exposed to temperatures not higher than 120-130°C and not lower than -18°C.

.

For air extraction we recommend the use of a pump with a maximum flow rate not exceeding 12 m2.

.

It will then be necessary to pay particular attention to the cleaning of the various components, taking care not to use too aggressive detergents and checking that there are no residues on the gasket that could compromise the vacuum seal over time. It is also important that, in case of dents or cracks, the container or lid is immediately replaced with a new one, in order to guarantee performance and hygiene over time.

.

Of course, our staff is at your disposal for any clarification.

.