NEWS

04 December 2018

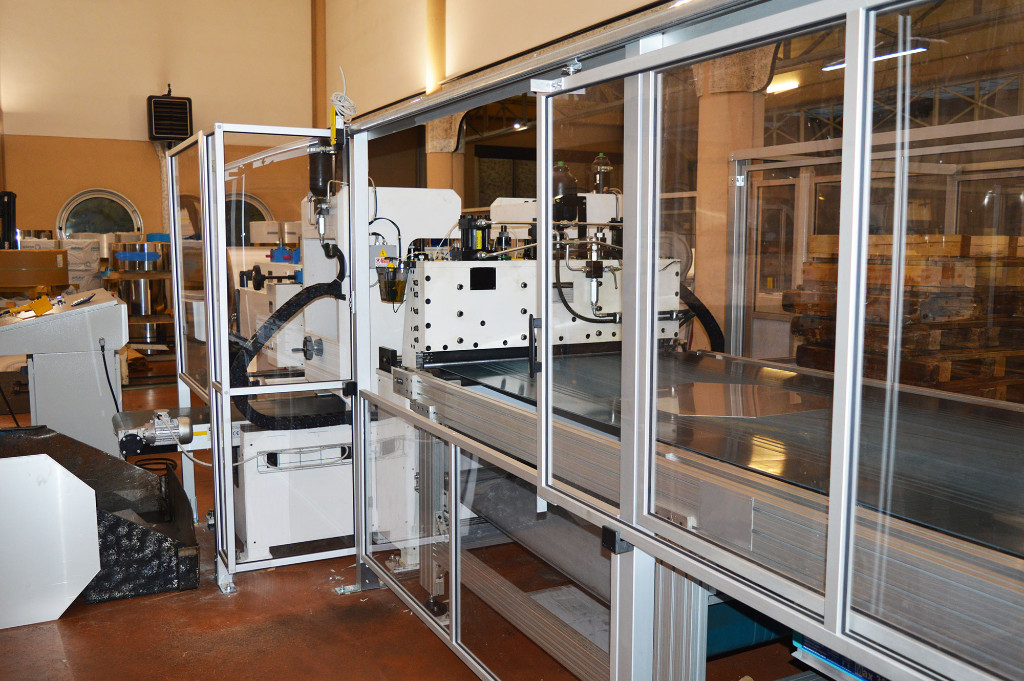

New cutting line

New longitudinal cutting line capable of cutting up to 10 tons of stainless steel per day

The process of digital transformation that companies are called upon to face in order to be competitive and leading players in the markets is not only a technological issue, but it is a matter of skills. Mori 2A has decided to undertake a technological and organisational development plan aimed at further improving work management, company performance monitoring and quality. The Government’s plan for Industry 4.0 stresses as a strategic measure the importance of human capital, which must be updated and in step with the new technological skills required. That’s why our project is a medium/long-term one that will have among its objectives a real involvement of our employees, so that INDUSTRY 4.0 is a real opportunity for growth for our company.

The automatic line uses the most modern technologies. All platforms SW used have been studied in agreement with the technicians of Siemens with the purpose of:

Reduce production costs

Energy saving

Operator safety

The software has been designed to optimize the sequence of production phases with the aim of minimizing the use of energy, working on downtime of the production phase, an estimated saving of about 15% of a traditional electromechanical system.