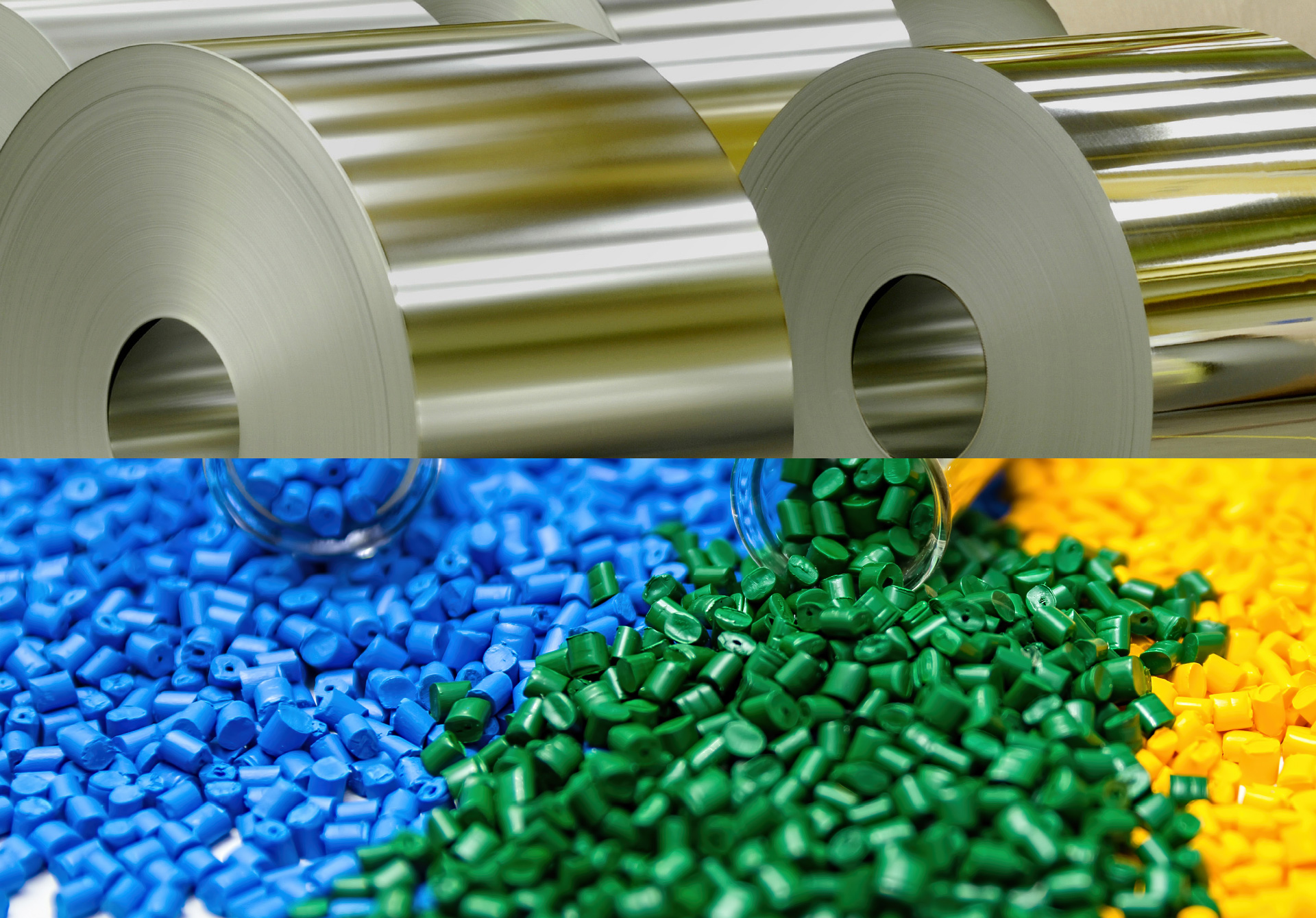

In the field of MOCA (materials and objects intended to come into contact with food), the quality of the raw material is an essential requirement that must be accompanied by a meticulous and accurate control, analysis and traceability system.

In addition to carefully evaluating suppliers on the basis of reliability and quality criteria, Mori 2A carries out rigorous checks throughout the production chain up to the finished product, thanks to a system of traceability and product batch tracking.

We are committed to ensuring the highest quality standards by applying Good Manufacturing Practices (GMP) in our factories.